In the market today are vibrations sensors produced at the highest quality by some manufacturers, and it would be good for you to know these various types for your machinery or industry use.

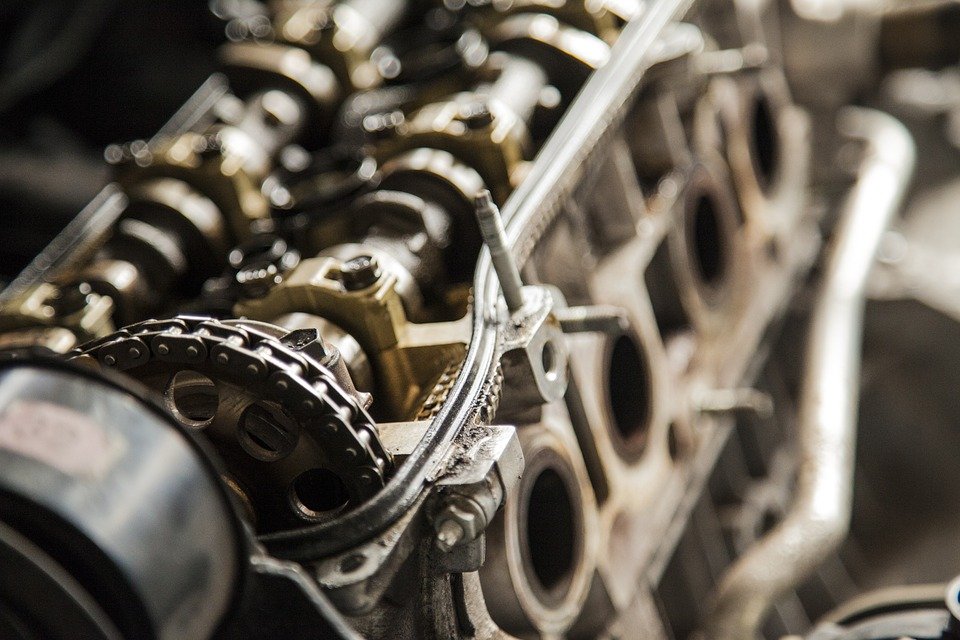

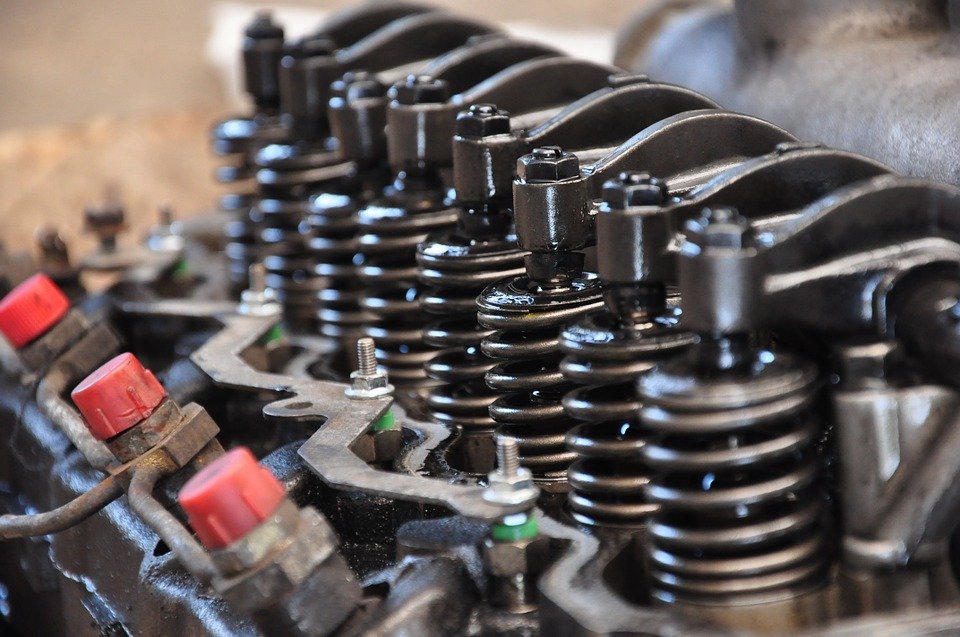

One great manner of protecting your machinery is the use of engine vibration sensors. Know that the most common reasons why there is an engine failure is overheating, leaks, improper lubrication, or shortage of proper lubrication. Those reasons can be prevented from occurring with the aid of engine vibration sensors, and when failure does happen, it will help you understand why the failure happened in the first place, leading you to solve the problem fast and to avoid the problem from happening soon.

Another protection of your machine is the motor vibration sensors that will aid in protecting the motors of your machine. Know that among the most common reasons why a motor fails would include electrical overload, low resistance, overheating, contamination, and undue vibration. Thousands of dollars and plenty of time will be saves when you use vibration sensor since the mentioned concerns will be prevented.

For pumps, its failure would be a result of the following reasons, like auxiliary seal flush levels inadequate monitoring, installation was done improperly, vibrations, overheating, suction is restricted and pressurized, and cavitation, with leaking as the most common reason why pumps fail. Pump vibration sensors becomes so helpful for pumps since these mentioned problems will be avoided in turning into a catastrophic disaster because this type of vibration sensor can detect issues at an early stage.

If you are working with reciprocating compressors or screw compressors, these will be protected if you have compressor vibration sensors on hand. The common reasons why these devices fail are changes in your air conditioning system or refrigeration system and others, so once your machine starts experiencing issues, it is better to install a compressor vibration sensor.

For centrifuges, the vibration sensor that can help it avoid failure is the next kind of vibration sensor called centrifuge sensor. By using this type of sensor, you will be preventing failure of your centrifuges due to reasons such as improper installation, improper balancing of tubes, buckets attachment incorrectly done, using tubes that are not meant for the speed of the machine, and an overloaded rotor maximum pass.

Damaged pieces, incorrect alignment, shaft or bearing that is loose, and poor inlet conditions are among the factor that can make your fans fail, and so in this case, it is recommended that you install fan vibration sensor. Know that there are companies that will create for you high quality sensors that will help you save time and money with this kind of preventive maintenance.

Your cooling tower may encounter some failure due to lack of maintenance, rise in temperature that is unexpected, excessive noise and vibration, loss of water, reduced flow of water, or cooling capacity that has lowered, and to avert a failure from happening, it is advisable that you install a cooling tower vibration sensor. You can learn more about vibration sensors here: https://www.britannica.com/science/ultrasonics#ref527462.